Welcome to the last installment in Rethinking Return-to-Work. If you didn’t have a chance to read the preceding posts, here is a quick recap with hyperlinks to the articles:

- Rethinking Return-to-Work (Part 1) focused on the economic impact of lost time or days away from work following a workplace injury including both hard costs that show up on a profit & loss statement and soft costs that are more difficult to quantify but are easily understood when observed in context.

- Rethinking Return-to-Work (Part 2) focused on why most programs don't work, what type of program works, what to call your program and who benefits when you do it right.

The focus of this article is implementation, including ideas to get your mind looking at different ways to do things by using real-life examples of injuries and how just a minor tweak in thinking can produce a radically different outcome for the employer and the injured employee.

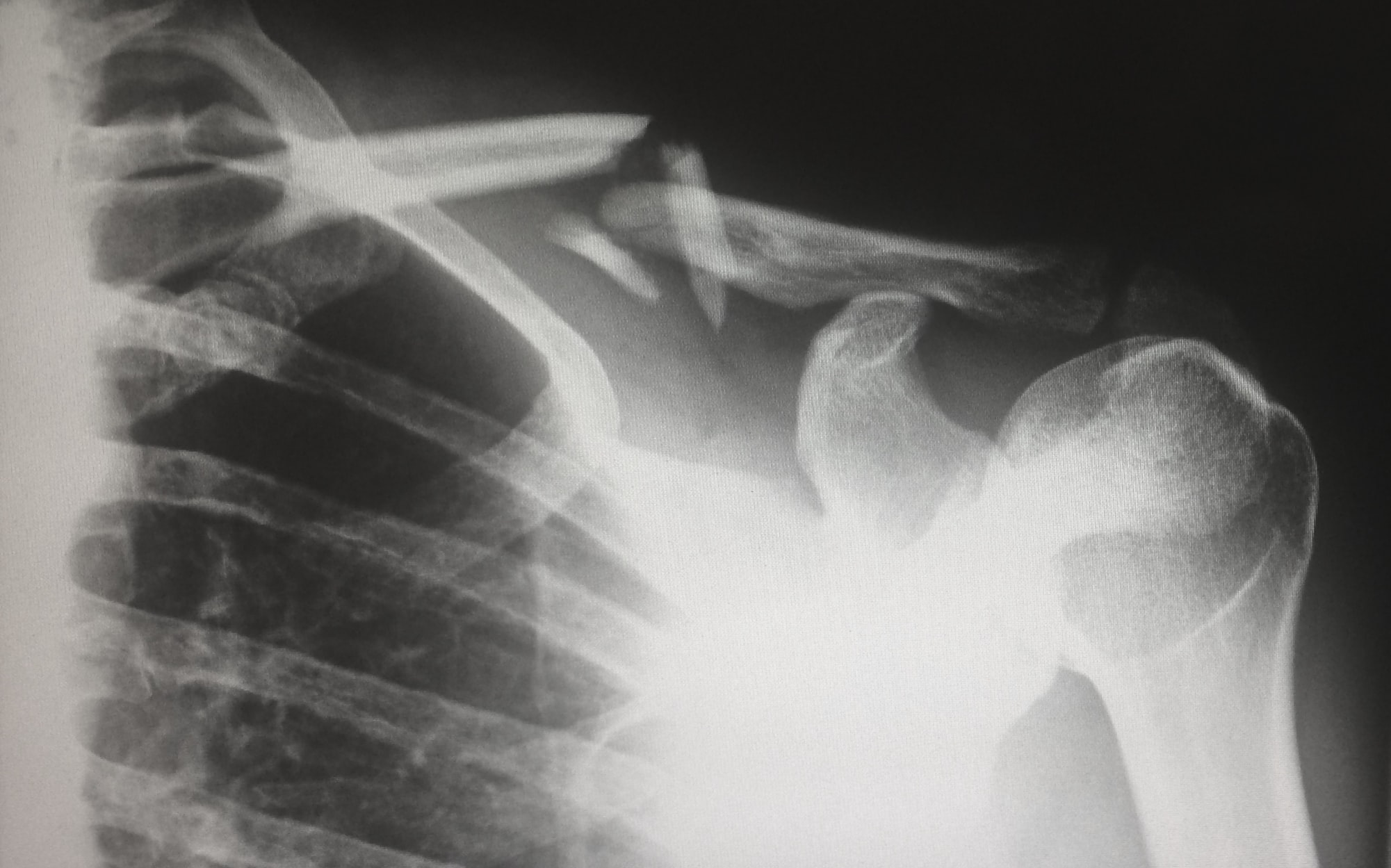

The first story is a tale of two shoulders. This employer experienced two nearly identical shoulder injuries to different employees in a relatively short period of time. With the first one, they thought they had done everything right. They knew that surgery was coming so they planned with the production staff around light duty once the employee returned and had substitute jobs ready to go. They allowed the insurance company claims rep to manage the claim and assumed that the return to work would be after about one week.

They did not take into consideration the window following surgery, when the employee may not be able to do too much. They did not communicate with the doctor in advance prior to the surgery. This error resulted in 18 days of lost time. How much work they prepared in advance and had ready upon the employee’s return meant nothing as the employer lost 18 potential “work” days.

With the second surgery, some keys things were done differently. The surgery was on Thursday and the employee was back to work on Monday. The employee had to be able to take meds, had to be able to sit or stand, their left arm was in a sling, and they could perform light duty only. Due to the medication the employee was kept off the job site and in a cubical with a computer where she was scanning documents for the quality department. This could have been ANY activity which allowed her restrictions to be accommodated and it was still better than the loss of 18 days.

What was the biggest difference? In both cases, the employer had committed to the employee’s recovery at work, but in the first case, they had failed to communicate with the medical professionals in advance. Why was this such a big deal? Based on what was paid for these two claims, the MOD impact for shoulder claim #1 was 300% higher than that of claim #2. Many employers neglect to consider the effect of lost time not only on morale, but also on the future cost of their insurance.

A third employer, a transmission repair shop, had an employee with a shoulder injury that also required surgery and the employee’s primary restriction would be that they could not raise their arm above their head for six weeks. With that restriction, there was no possibility of him performing any of the essential functions of his job since the vehicles were overhead on a lift while the repairs were performed. The employer asked the doctor if there would be any restriction that would keep them from bringing the employee back to work immediately if everything he did was from a recliner and didn’t require anything to do with shoulder movement. The doctor had no problem with that since the employee likely would have been doing the same thing at home.

Why would they want to bring the employee back to work just to sit in a recliner for six weeks? As it turned out, he was the only employee who was experienced in rebuilding transmissions. This was a perfect opportunity for them to train another employee. While it was always difficult to find the time before, the injury put them in a position where they had no other option and ample time for training. Although the employee was initially not happy with the arrangement, eventually all sides realized the benefits. The employer was able to solve a problem and the employee was paid his full wage and retained all the benefits of employment while remaining engaged with his employer and his fellow employees.

Another creative way to accommodate restrictions is by using the concept of job carving. Job carving involves modifying a job such that it can be successfully performed by an individual with disabilities, while simultaneously meeting the needs of an employer. Job carving typically involves conducting a task analysis of a job by breaking it down into a series of smaller steps. This allows an employer to identify which parts of a job might be completed by an individual with restrictions or disabilities.

Skills carved out from several jobs can be combined into a new job that is tailored to fit the skills, preferences, and level of support required for an individual while meeting the needs of the employer. While other employees may have to pick up tasks that can’t be performed by their injured co-worker, the tasks that are transferred to the injured party usually more than make up for that and no productivity is lost during the injury recovery period. This also allows the employer to accommodate restrictions that may be long-term or permanent, so they are ADA compliant.

At the end of the day, the keys to successful implementation involve advanced analysis and planning, communication with the medical provider and creativity when looking at ways to keep injured employees actively engaged with you and their fellow employees. When it comes to accommodating restrictions, almost nothing is too crazy!

As always, please don't hesitate to reach out with any questions or requests for additional information.

About the Author:

Ray Gage, Director of WalkerHughes Allen County Office, is a Master Work Comp Advisor who's passion and life's work is to help sophisticated, process-oriented businesses create safe, healthy, productive workplaces, and as a result, more profitable firms. For more information on Automate Safety along with the other tools offered by WalkerHughes to assist in your quest for Zero Injuries, contact Ray at r.gage@walkerhughes.com or by phone at 260-627-3641 with any questions or inquiries.